1.Meets International standards.

Covers various applications from JEDEC, IEC standards,automobile related specification test to screening. Suitable for condensation test and durability to automobile parts .

2.Balanced Temperature (& Humidity)Control system(BT(H)C system)and PID control function.

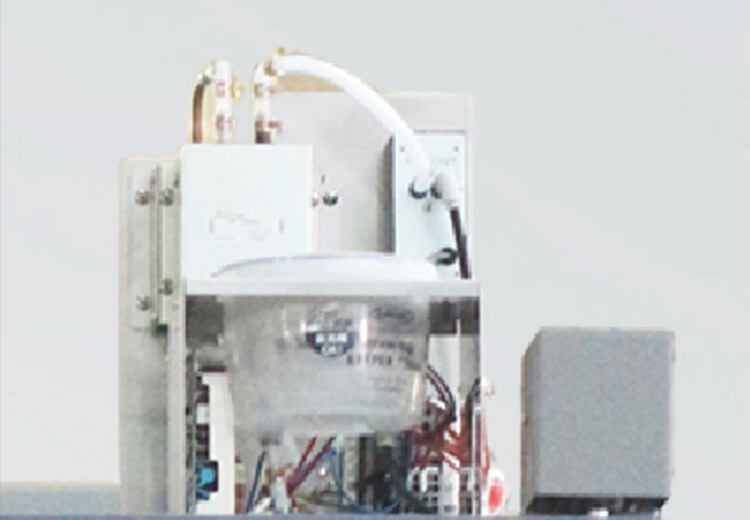

Using the Balanced Temperature (& Humidity)Control system(BT(H)C system) to control,provides hightly accurate temperature/humidity environment.Consisting of PID controlled refrigerrator,and instrumentation,which delivers hight speed processing.

3.Uniform and reproducible temperature rate of change, temperature ramp control function.

The chamber is available that achieves a temperature change rate of 1~20℃ K/min . In addition, controlled humidity from 10 to 95% is an available feature.

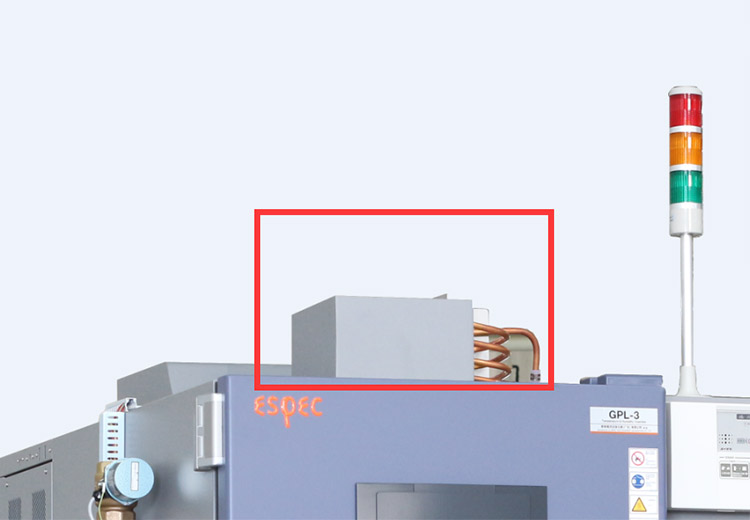

4.Air-cooled models available. as option.

High performance test chambers usually mean water cooling utilities are required. The GFS/G-400 models of are available with integrated air-cooling. The condenser is mounted on top with low speed fans for minimal noise impact.

5.Standard program instrumentationcan suit various applications:

3 constant operation modes:Program /Constant/Cycle Operation. Features programmed operation with operational settings such as constant mode and automatic start/stop.

·Suitable for a range of applications from temperature-characteristics testing to heat/humidification treatment and drying. Programmed operation now allows storing 40 program operation patterns, each up to 99 steps. Provides a wide range of functions, including temperature ramp settings and a maximum of 999 repeat cycles.

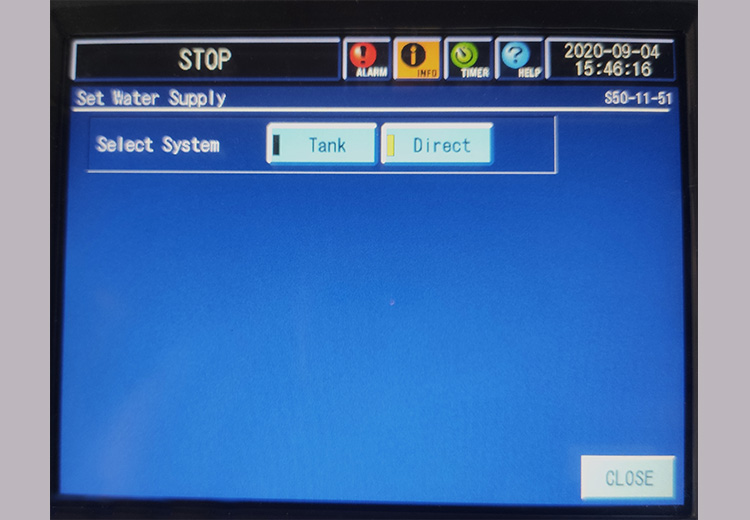

6.Color LCD touch panel.

Easy-to-use color LCD touch panel is included as standard. It is much easier to set various patterns of Constant-, Program-, Remote-Operation to meet various testing conditions.

7.Multilingual display.

Can change the display lauguage from English to Japanese,Simplified Chinese,Traditional Chinese or Korean at any time from the lanuage icon on the top of the display.

8.USB output of trend graph data.

Data can be recorded directly to a USB flash drive,backup and measurement intervals and other setting can be configured as required.

9.Interface (option)for device communication can be selected between RS-485, GPIB,Web Lan and RS-232C.

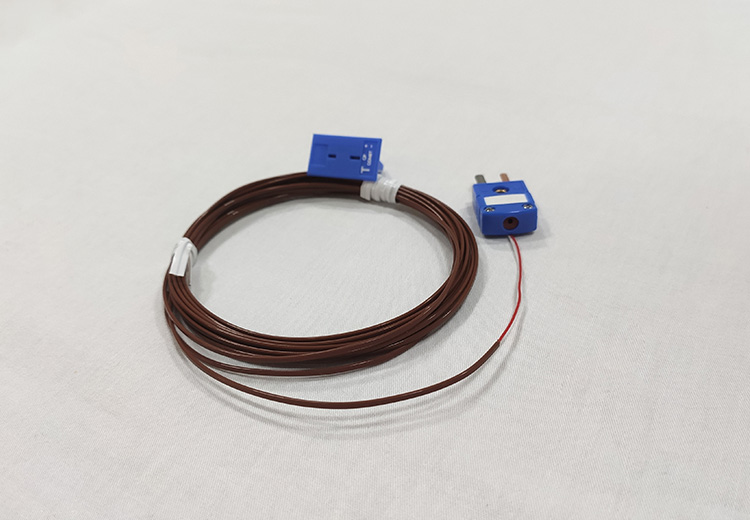

10.Cable ports on both sides (θ50) as standard to allow easy wiring access.

11.Core parts are inported from Japan and America,which are same with the ESPEC CORP.

12.New models GFS/G-400-25,GFG-200-25 are more suitable for the reliability test of semiconductor electronic components

Suitable for semiconductor electronic devices, solder joint life assessment, and reliability testing of semiconductor packaging.

Suitable for reliability testing of automotive electronic components, automotive battery management systems (BMS), automotive electronic control systems, etc.

Able to effectively meet the requirements and industry standards of high-end electronic, semiconductor, and automotive industry customers.

Can meet the evaluation and testing requirements of JEDEC and IEC standards.

JESD22-A104F(*Please consult the sales company first)

IEC60749-25(*Please consult the sales company first)

IEC60068-2-14 Nb((JIS C 60068-2-14 Nb))

EIAJ ED-2531B Nb

JESD22-A105C

IPC-9701

IPC-TM-650 2.6.6 B

LV 124 L-03V

SAE J1211

(Note: Load: 5kg epoxy plate, 4kg stainless steel, no heat)

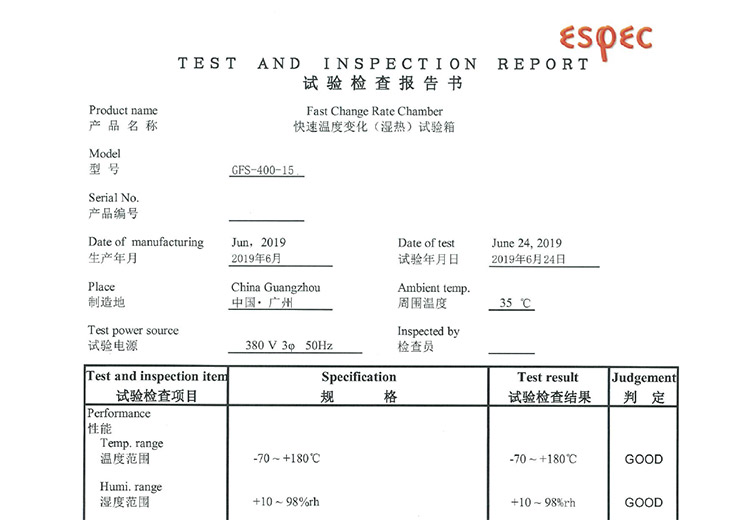

※1 The temperature chamber's performance values are based on GB/T5170.2,and IEC60068-3-5.And humidity chamber's performance values are based on GB/T5170.5 and IEC60068-3-6.Performance figures aregiven for a +23℃ ambient temperature, relative humidity 65±20% RH, rated voltage, with no specimens inside the test area.

※2 The temperature inside chamber is +20℃.

※3 Excluding protrusions.Dimensions in [] included protrusions.

※4 This temperature Heat up & pull down rate is the value of the rate that 10% before and after the total temperature interval is removed.