Please feel free to contact us in English at the following hot line. 0086+20+84528103

- HOME

-

PRODUCTS

PRODUCTS

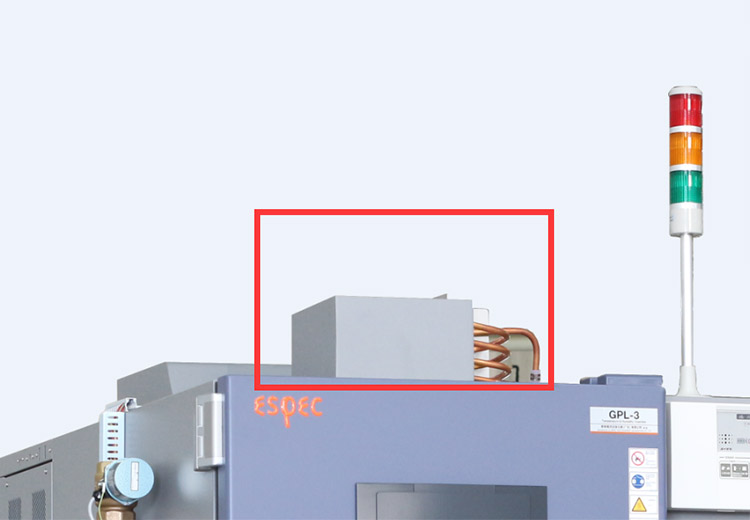

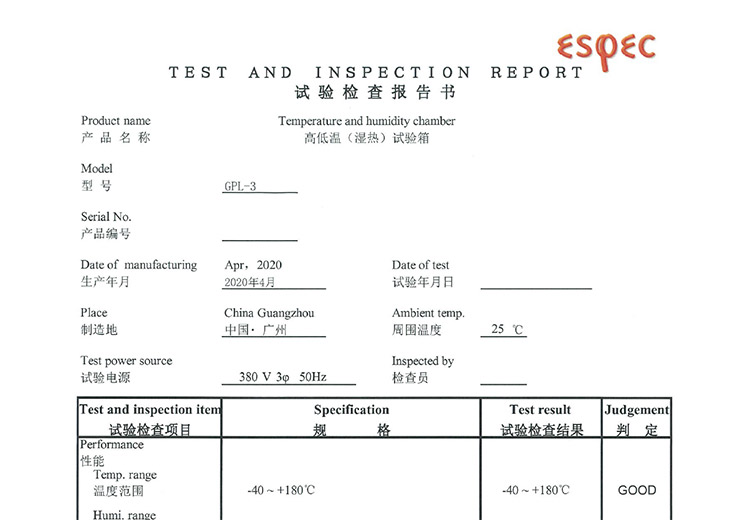

Rapid-Rate Temperature (& Humidity)Cycle Chamber Series

Compact Rapid Temperature Change(humidity) Chamber-GMS Series

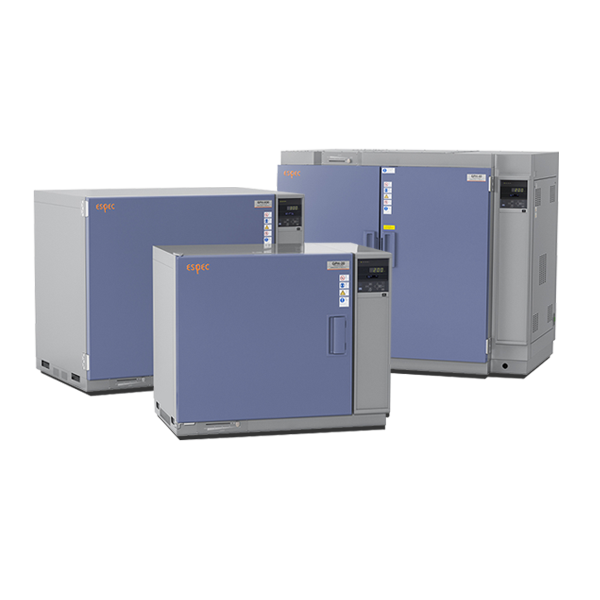

Bench-Top Type Temperature (& Humidity) Chamber

Temperature (& Humidity) Chamber Series

Low Humidity Type Temperature Humidity Chamber Series

Temperature (& Humidity) Chamber(Wide view)Series

Temperature (& Humidity) Chamber(for Battery test)

High Performance Temperature (Humidity) Chamber

Thermal Shock Chamber -GTSD series

Compact Ultra low Temperature Chamber-GMC

- MARKETS

- SERVICE SUPPORT

- ABOUT ESPEC

- ABOUT US

- CONTACT US