ADDRESS:NO.14, Meide 2nd Road, Pearl River Street, NanSha, GuangZhou.China.

E-MAIL:INFO@gd-espec.com

With the continuous innovation of science and technology, semiconductor technology is also increasingly updated and the demand for reliability testing in the semiconductor industry is increasing. In response to the high heat and high load testing needs of semiconductors and electronic components, Espec (Guangdong) has developed the high performance temperature(humidity)chamber - GH series, which can achieve faster temperature rise and fall rates while maintaining the advantages of the standard GP series, and can correspond to high load and hight heat reliability tests with a maximum allowable heat load of up to 4500W.

Contact

Can achieve higher performance

Compared to GP chambers, it has a faster temperature rise and fall rate: rise rate: 7°C/min, fall rate: 3~5°C/min. Humidity range: 10% ~ 98RH.

Corresponding high heat and high load tests

Suitable for reliability testing of electronic components related to semiconductors and automotive components, as it can handle high heat and high loads up to 4500W.

Easy to further performance modifications,hight expansibility

The structure is easier to modify, e.g. the dimensions custom modifications; the inner groove connection modification of two chamber.

It is easier to carry out modifications related to improving performance.

Balanced Temperature (&Humidity)Control system(BTHC system)and PID control function.

Using the BTHC system to control,provides hightly accurate temperature/humidity environment.Consisting of PID controlled refrigerrator,and instrumentation,which delivers hight speed processing.

Standard program instrumentationcan suit various applications:

3 constant operation modes:Program /Constant/Cycle Operation. Features programmed operation with operational settings such as constant mode and automatic start/stop.

Programmed operation now allows storing 40 program operation patterns, each up to 99 steps. Provides a wide range of functions, including temperature ramp settings and a maximum of 999 repeat cycles.

Color LCD touch paneland Multilingual display.

Easy-to-use color LCD touch panel is included as standard. It is much easier to set various patterns of Constant-, Program-, Remote-Operation to meet various testing conditions.

Multilingual display.

Can change the display lauguage from English to Simplified Chinese, at any time from the lanuage icon on the top of the display.

Interface (option)for device communication can be selected between RS-485, GPIB,Web Lan and RS-232C.

Cable ports on both sides (θ50) as standard to allow easy wiring access.

USB output of trend graph data.

Data can be recorded directly to a USB flash drive,backup and measurement intervals and other setting can be configured as required.

A wide range of options can be added to meet the diverse needs of customers.

Additional safety options such as pressure relief valves, smoke sensors, Emergency push stop button, alarm output terminals and Three Color Status indicator Warning Lights are available.

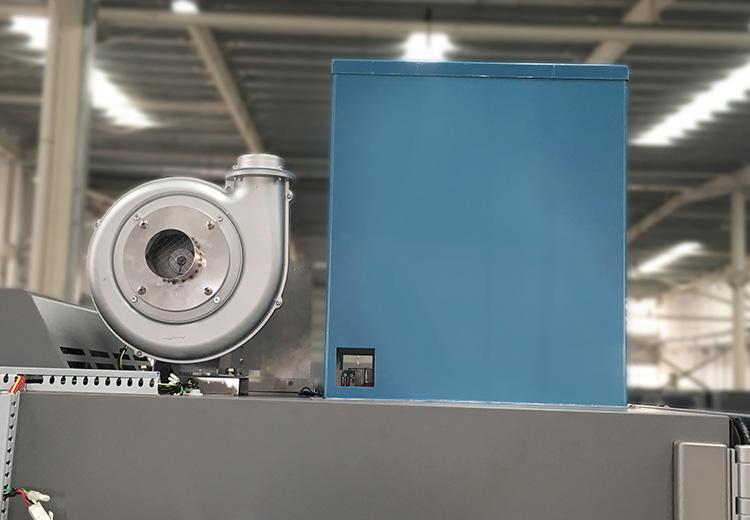

Air-cooled specifications as standard for ease of movement and installation.

| Description | Model | Temp. Range | Hum. Control | Hum. range rh | Volume | Inside dimensions in mm (WxHxD) | Outside dimensions in mm (excl. projection) |

| High Performance Temperature Humidity Chamber | GHL-400 | -40℃~+180℃ | YES | 10%~98%rh | 400L | 600×830×800 | 800×1753×2200 |

| High Performance Temperature Humidity Chamber | GHL-1000 | -40℃~+180℃ | YES | 10%~98%rh | 980L | 1000×980×1000 | 1200×1903×2500 |

| High Performance Temperature Humidity Chamber | GHS-400 | -70℃~+180℃ | YES | 10%~98%rh | 400L | 600×830×800 | 800×1753×2200 |

| High Performance Temperature Humidity Chamber | GHS-1000 | -70℃~+180℃ | YES | 10%~98%rh | 980L | 1000×980×1000 | 1200×1903×2500 |

※1 The temperature chamber's performance values are based on GB/T5170.2,and IEC60068-3-5.And humidity chamber's performance values are based on GB/T5170.5 and IEC60068-3-6.Performance figures aregiven for a +23℃ ambient temperature, relative humidity 65±20% RH, rated voltage, with no specimens inside the test area.

※2 The temperature inside chamber is +20℃.

※3 This temperature Heat up & pull down rate is the value of the rate that 10% before and after the total temperature interval is removed.

Outputs chamber temperature and humidity.

Records temperature and humidity of each section such as the temperature inside the chamber.

Detects the humidity inside chamber.

* Maximum value of humidity is 95%.

* Humidity type chamber only.

Sensors are attached to the specimen to allow exposure tests that provide temperature stress to the specimen.

*Unable to be fitted together with Recorder output terminal(Temp).

Fine wick of the same kind as the accessories.

FW-5(24 wicks)

*Humidity type chamber only.

Communication ports to connect the chamber to a PC.

Alternatives:Web(Lan)/RS-485/RS-232C/GPIB

A through hole provide on the wall of chamber.

Available dimensions: θ50/θ100/θ150.

*1.with cap.

2.Could be added into the left/right side of chamber(standard position only ).

Non-standard position please Inquire the sale company for details.

Comes with the cable port. Prevents airleakage from the cable port.

Inside diameter: θ50/θ100/θ150.

* θ25mm is non-standard option.

Used for the placement of specimens in the test area and reduce the risk of short circuits.

Surface electrophoresis on the shelf &shelf brackets (black).

For specimens whose weight exceeds the standard shelf load capacity.

Alternatives:50KG/100KG.

*Heavy-duty shelf 50KG/100KG have to be fitted with Heavy-duty shelf(Reinforce 50KG/100KG).

Used for the placement of heavy specimens or tools on the floor inside chamber .

Supports an equally distributed load:100KG/200KG/300KG.

*1Standard floor load reinforcement:70KG.

*2 Chamber total load resistance:Sum of the loading weight of all shelves and the floor area loading weight.

Enable long-term continuous operation under a temperature setting of +15℃ or higher,without the need to interrupt for defrosting.

Enables continuous supply of pure water for the humidifier.

*Humidity type chamber only.

Safety device.

Purpose: This contact signal terminal is for sending error alerts to a remote location during safety actions.

*1 Unable to be fitted together with three Color Status indicator Warning Lights .

Safety device,enables manual emergency stop of the chamber.

*Purpose:Protecting the specimens and chambers.

Safety device.

Purpose: Provides a view of the chamber status from a remote location.

With buzzer/Without buzzer

*1:Unable to be fitted together with Alarm output terminal.

*2:Please contact the sales company if you need to change the action and light sequence.

Safety device.

Purpose: The inner side of the Viewing Window Append Stencil.

Safety device.

Purpose: Increase the strength of the door lock.

Lever type or dial lock type can be selected.

Safety device.

Purpose: When an abnormality is detected inside chamber, the fire extinguishing device is started, and CO2 is injected into the test box to ensure the safetyinside chamber.

*1:The chamber will occur an external machine abnormal alarm and stop running when the fire extinguishing device is abnormal.

*2:Please contact the sales company if you need a different type of Fire Extinguishing Device.

Safety device.

Purpose: When flammable gas is detected inside chamber,the corresponding actionswill be taken.

Action Sequence: The chamber will occur an external machine abnormal alarm and stop running when the device is abnormal or the Gas Sensor occurred 1 segment alarm( 24%LEL(9600ppm)).

The Fire Extinguishing Device will start up when the Gas Sensor occurred 2 segment alarm( 24%LEL(9600ppm)).

*1:Please contact the sales company if you need a different type of Gas Sensor.

Safety device.

Purpose: When CO/CO2/H2 gas is detected inside chamber, the corresponding actions will be taken. *Please contact the sales company for specific requirements.

Safety device.

Purpose: Exhaust the gas inside the chamber forcibly.

Action: Automatically open when the Overheat Protector and Smoke Sensor alarmed.

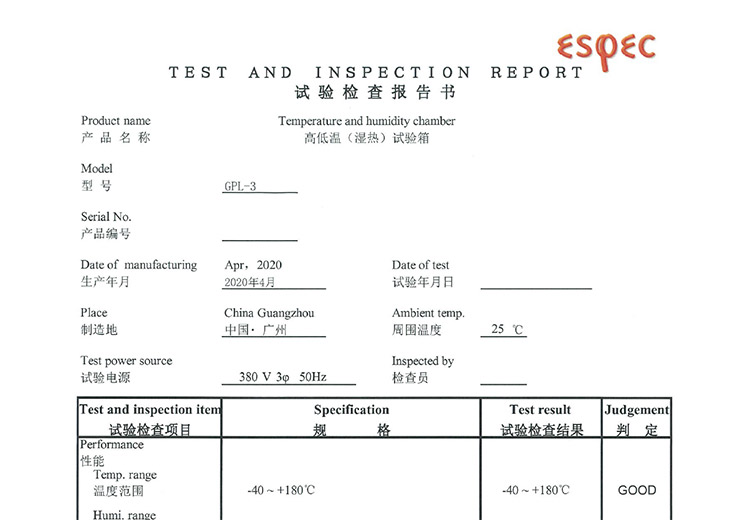

Test according to GB standard and issue test report.

*Base on the actual machine test results and for customer reference only. The report does not have the qualification as a third-party testing agency.

Test report issue by ESPEC guangdong,

Same as standard accessories. shipped with chamber.

Safety device.

Purpose: Detect the overheating of the battery(specimen) surface.

*Notice: The sensor is independent.

Safety device.

Purpose: Draw the air inside the chamber. Stop the chamber operation and open the air supply and exhaust damper if the smoke had be found.

Preparation of a power cable,temperature sensor and a grounding wire for additional installation in the future.

Observe and operate the specimen insidechamber from the inner glass door.The inner glass door can be equipped with hand-in ports.

Hand-in ports:1pair(400/1000 type),2 pairs(1000 type)

*1.Additional operation hand-in ports may have an impact on

Used for the placement of specimens in the test area.

Same as standard shelf.

For specimens whose weight exceeds the standard shelf load capacity.

Alternatives:30KG/50KG/100KG.

Used during longterm low-temperature operation, which can maintain the positive pressure inside chamber and ensure that no frost is formed in the test chamber.

Safety device.

Purpose: Add pressure relief valve on the top of the Chamber.Pressure relief when the internal pressure of the test chamber rises.

Action: The Breaker will turn off and the chamber will stop When the pressure relief valve is opened.

*1: This device can not prevent explosions and fire in the chamber.

Safety device.

Purpose: Exhaust the gas inside the chamber.

Action: Automatically open when the Overheat Protector and Smoke Sensor alarmed.